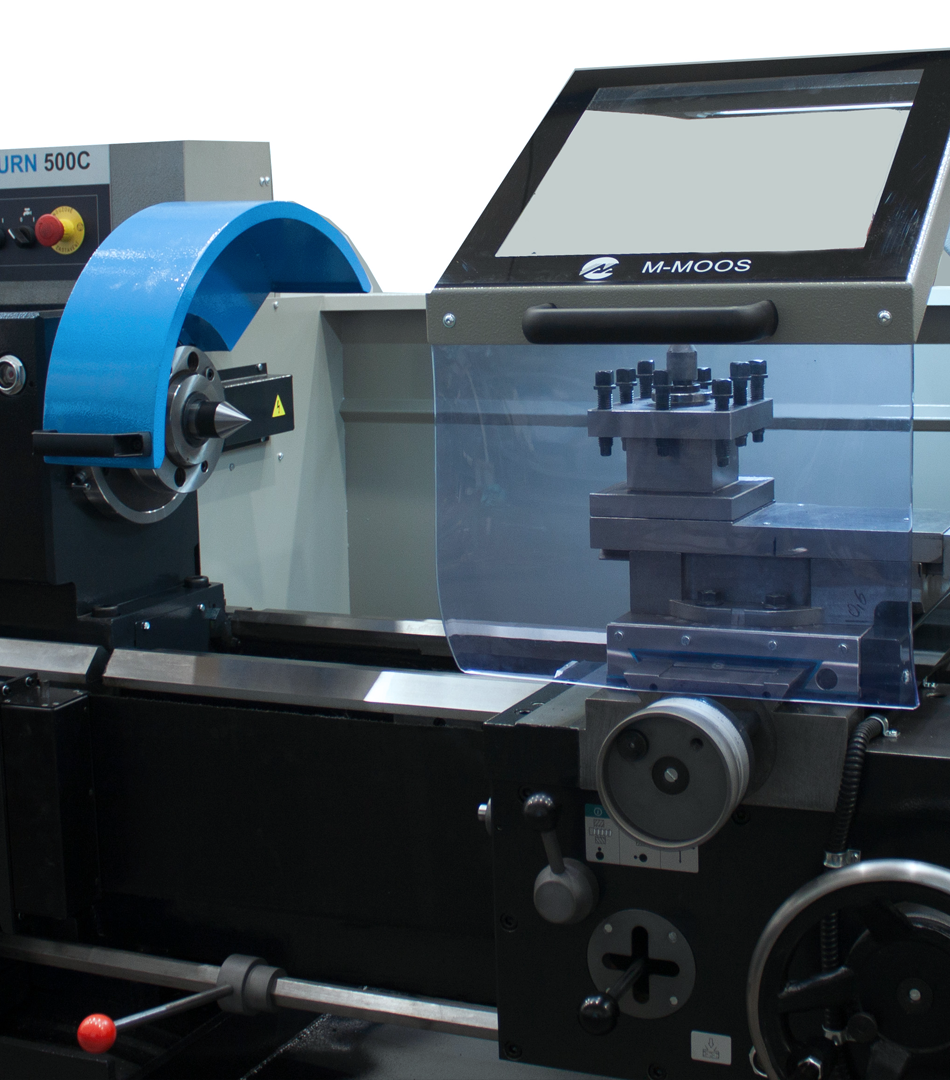

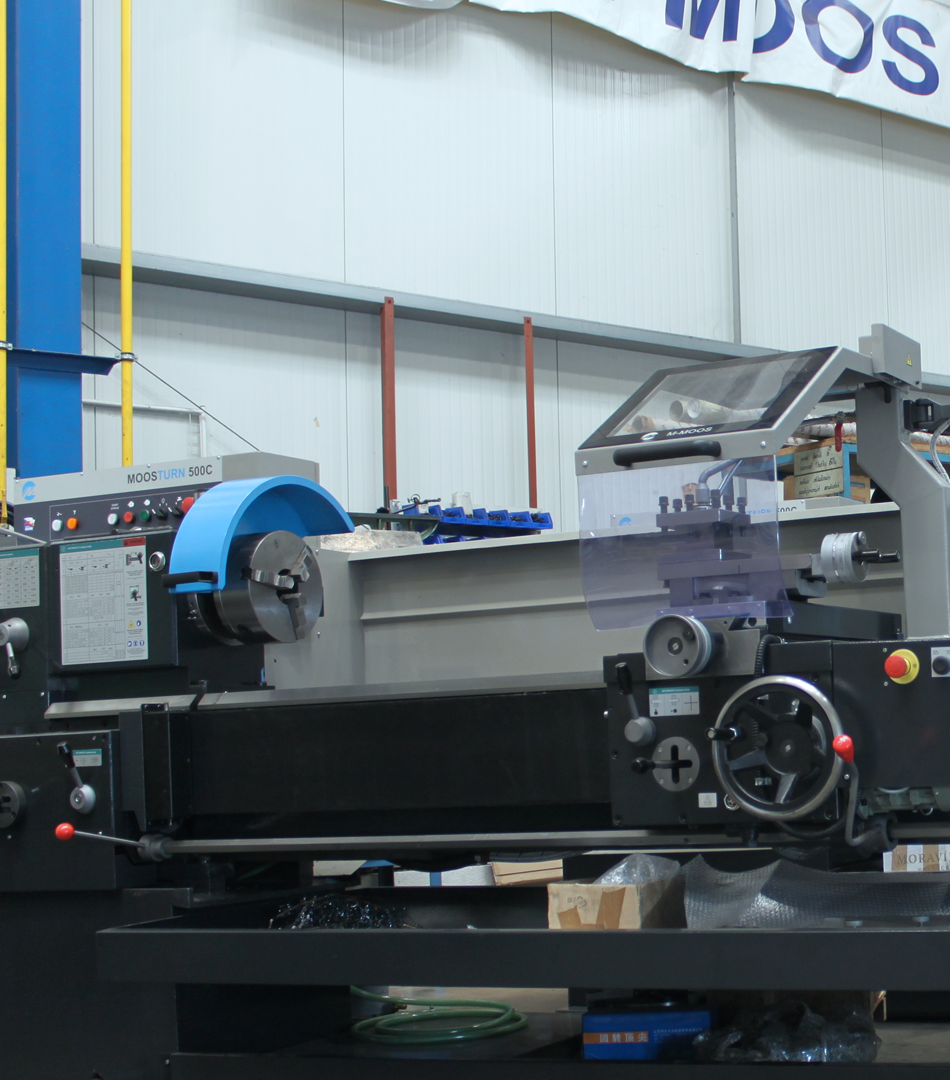

Center Lathes made in the Czech Republic

precise small series production and assembly

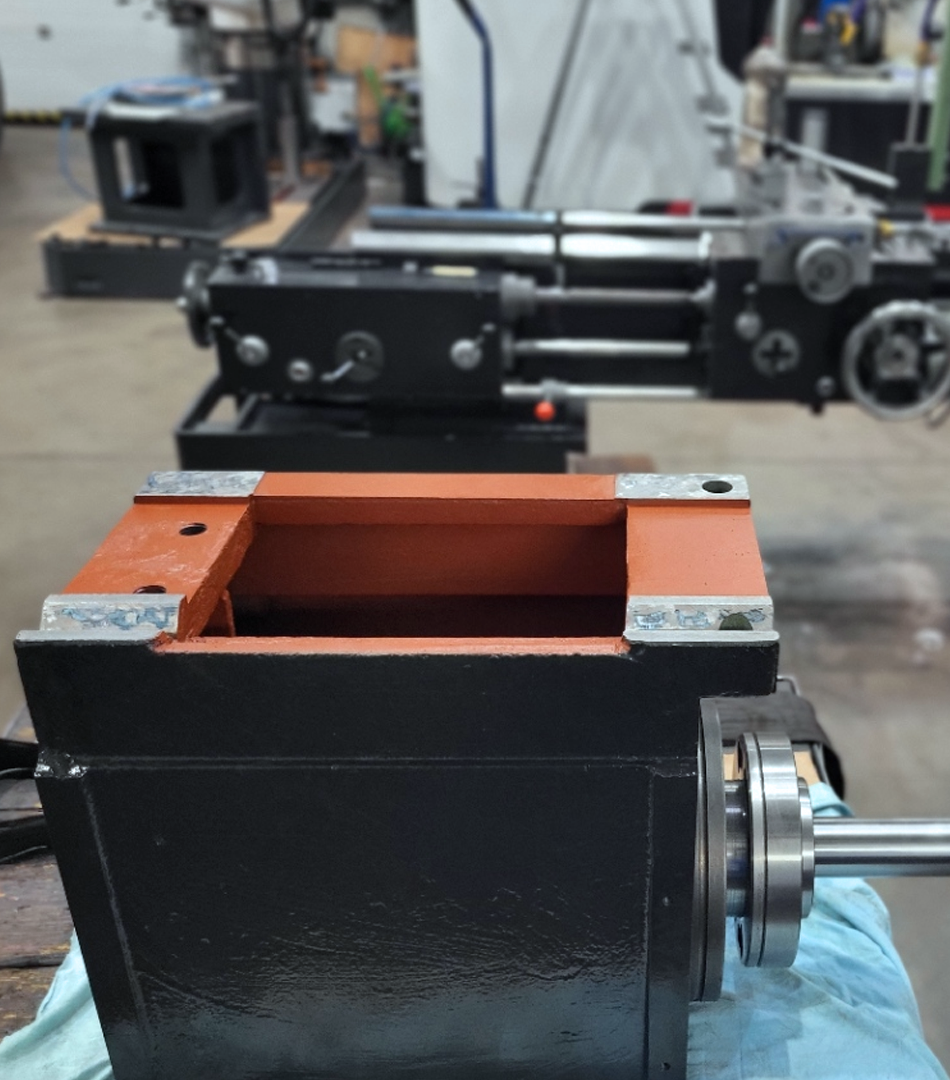

Center lathes from the MoosTurn brand follow on from the popular SN series of lathes from TOS, which have been among the European leaders for more than 70 years. This series has been produced in many versions since the 1950s, so it has been thoroughly tested by several generations of turners across the continent. Thanks to the general repairs it has been carrying out since 1993, the M-MOOS company has managed to preserve the know-how of production and spare parts, so it has been able to continue with the original production.

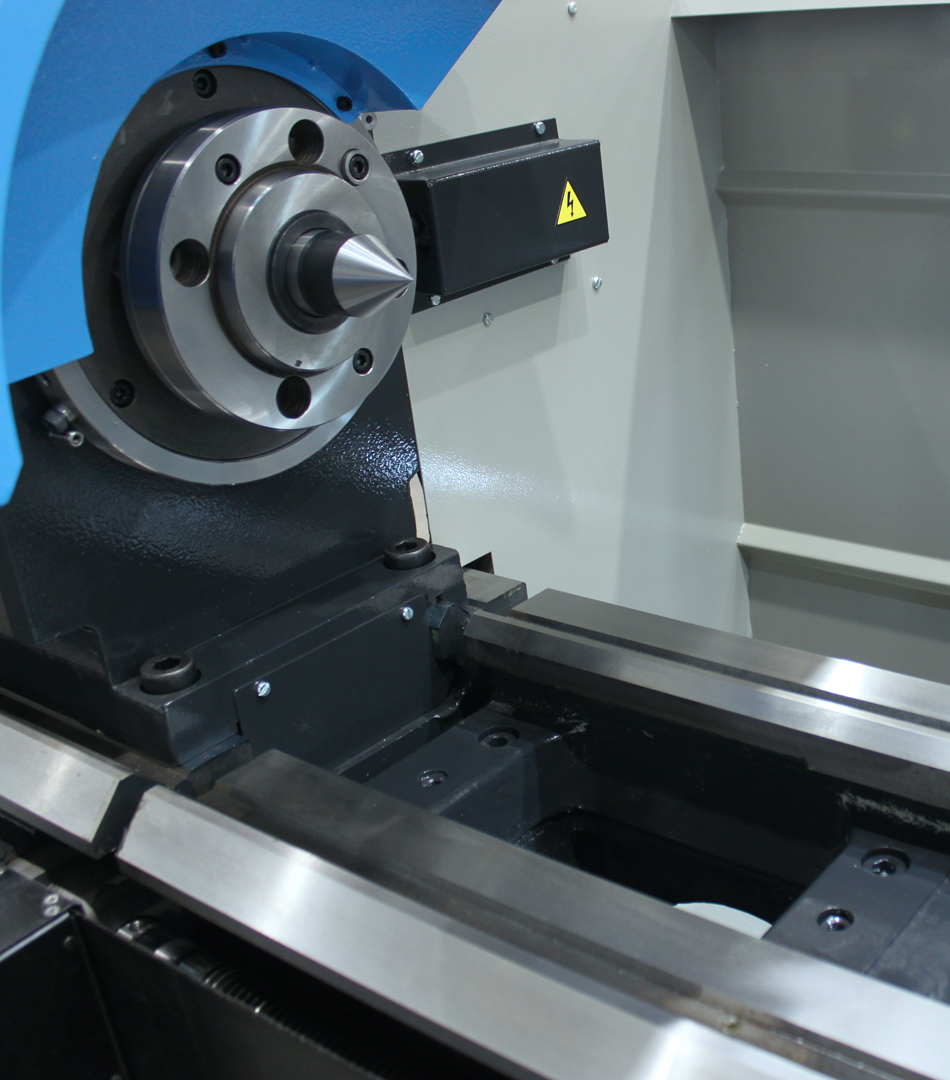

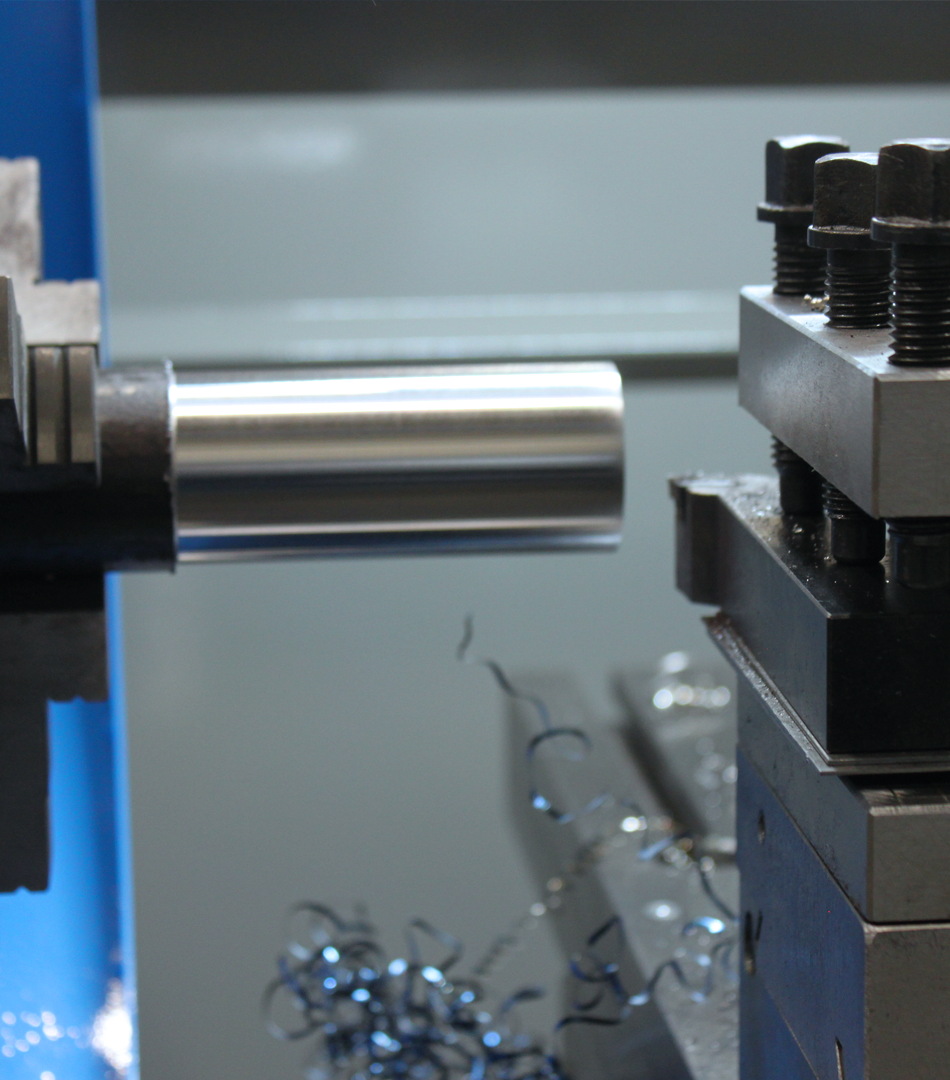

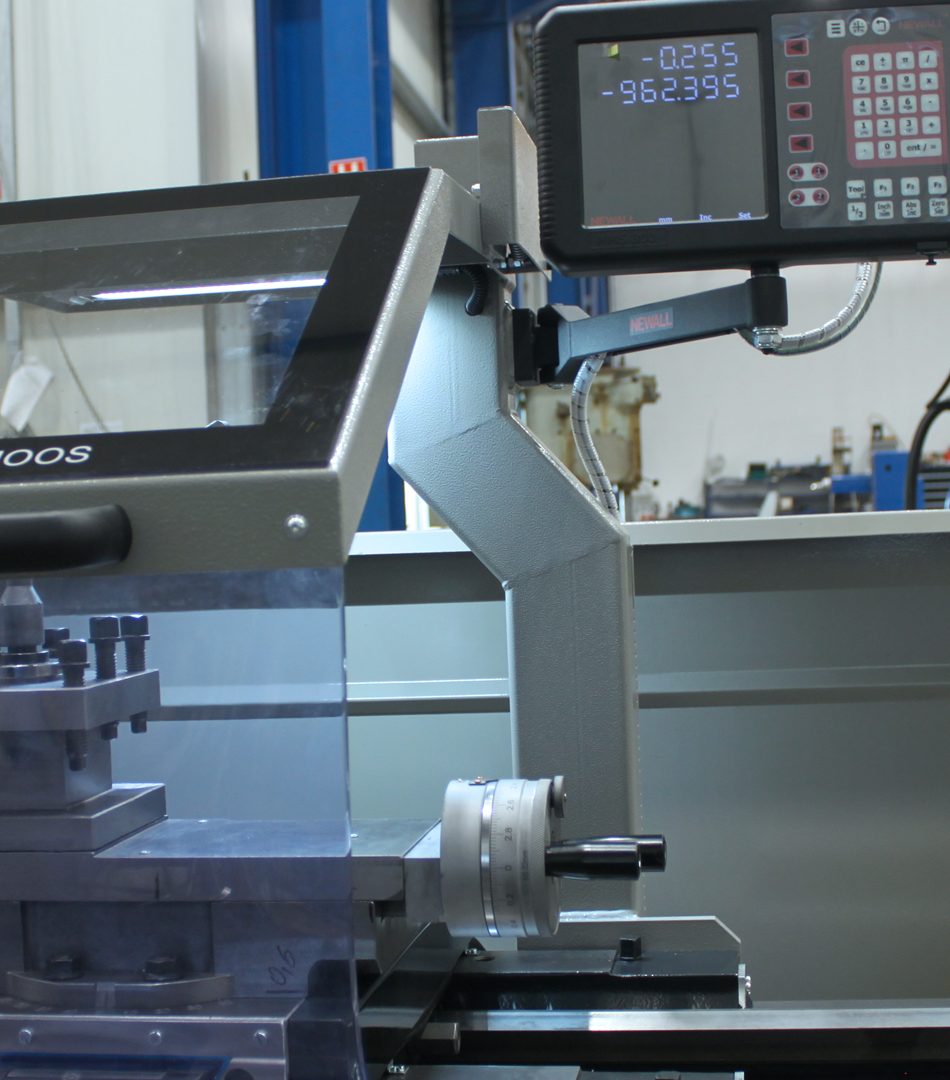

The main feature of these lathes is the accuracy of the machine and very successful workshop processing. Quality is guaranteed by piece production, where great emphasis is placed on manual fitting. The machines are manufactured with high precision according to DIN standards and are available in both metric and inch versions, with supports and a wide range of accessories included.

They are designed for roughing and finishing work on medium-sized shaft and flange components, as well as for thread cutting, boring, turning cones and various shaped rotating surfaces

| Standard equipment and configuration |

| 1 |

Max. swing diameter over bed 710 mm |

12 |

Workpiece cooling system |

| 2 |

Turning diameter over slide 420 mm |

13 |

Work lighting |

| 3 |

Turning diameter when removing bridge 910 mm |

14 |

Electr. version 3x400V /50Hz |

| 4 |

Spindle bore 73,5 mm |

15 |

Face plate |

| 5 |

Spindle speed 22-2000 rpm |

16 |

Fixed steady rest small |

| 6 |

Guide screw and rod protection |

17 |

Movable steady rest |

| 7 |

Replaceable wheel set |

18 |

Rigid cast iron construction |

| 8 |

4-position cutter head |

19 |

Spindle end ISO 702/III – B6 (Bayonet) |

| 9 |

Full length rear guard |

20 |

Instructions for use |

| 10 |

Cutter head guard |

21 |

Engine power 7.5 kW |

| 11 |

Chuck Safety Guard |

22 |

Leveling Washers and Screws |