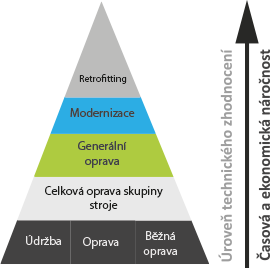

What is Overhaul? First of all, it is a total disassembly, ground surfaces and perfect geometry. It returns the machine to working life. The level of wear is considerable today. This raises the demands on the quality of repairs. 20 years ago, a handy locksmith in a garage could perform a decent GO. Unfortunately, those days are gone.

Today, it is necessary to disassemble the machine down to the last component and check every gear. This is the only way to guarantee that the machine will work reliably for another 10 years and the investments made will be optimally spent.

Do you wish to prepare a quote or need to consult the possibility of repair or modernization.

A machine after GO has a technical value of 90 to 95% of a factory-new, identical or similar type machine.

effective solution for disposing of old machines

more than 1300 machine tools after ovehauls

more than 1300 machines after overhauls and modernization

own spare part production

Since 2001, we have been performing complete conversions of used machines to CNC controlled ones. Conversion of a conventional machine to a numerically controlled machine consists of a complete overhaul, replacement of existing screws with precision ball screws, installation of drives and a control system.

The choice of control system depends on the customer's wishes and habits. The possibility of choosing a system depends on the user's needs. The customer can choose a Sinumerik, Heidenhain or Fanuc control system. Our company has its own employees who are regularly trained and are able to create PLC machines.

We provide a minimum 12-month warranty on machines. A longer period can be agreed upon with the customer. An integral part of the delivery is an accuracy protocol, an inspection report and additional electrical documentation.

Would you like to make a quote or discuss the possibility of upgrading? Please do not hesitate to contact our representative.

Which machines are worth retrofitting today? Theoretically, every machine can be modernized. But rebuilding heavy, large or special machine tools is definitely a sensible investment. In this category, it really pays off. With new machines, you pay for the mass of the machine. With a rebuild, you only pay for the cost of labor and new components.

So the conversion is certainly economically advantageous. Moreover, thanks to the matured cast iron, these old machines have much greater rigidity than new machines. :

Retrofitting is definitely worthwhile for these types of machines:

-universal lathes from a rotating diameter of 800 mm and more

-wheel lathes - e.g. Rafamet

-horizontal boring machines

-vertical lathes

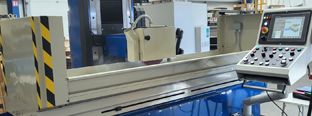

-bed milling machines

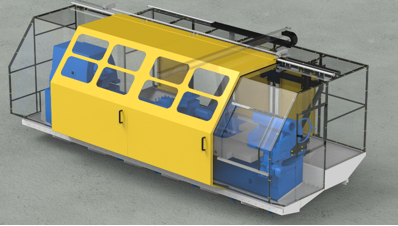

Used lathe SU 90 /3000 before modernization

includes a design for the placement of control elements and covering

Final solution SU 90 CNC with Simens Sinumerik 828D

Swing over bed 380 mm, Distance between center: 750/1000/1250 mm

We provide overhauls and middle repair

Swing over bed 380 mm, Distance between center: 1000/1500/2000 mm

We provide overhauls and middle repair

Swing over bed 320-710 mm, Distance between center: 750-4000 mm

We provide overhauls and middle repair

Swing over bed 630-1000 mm, Distance between center: 1250-8000 mm

Modernization to CNC, ovehauls

Swing over bed 320-800 mm, Distance between center: 750-4000 mm

We provide overhauls and middle repair

Swing over bed 1000-2000 mm, Distance between center: 3000-12000 mm

Modernization to CNC, ovehauls

Drilling capacity 50 - 80 mm

We provide overhauls and middle repair

Ve With working table size 300 - 1800mm

We provide overhauls and middle repair

Demonstration of the implementation of partial carousel modernization SK-16

We provide Overhauls and Modernization

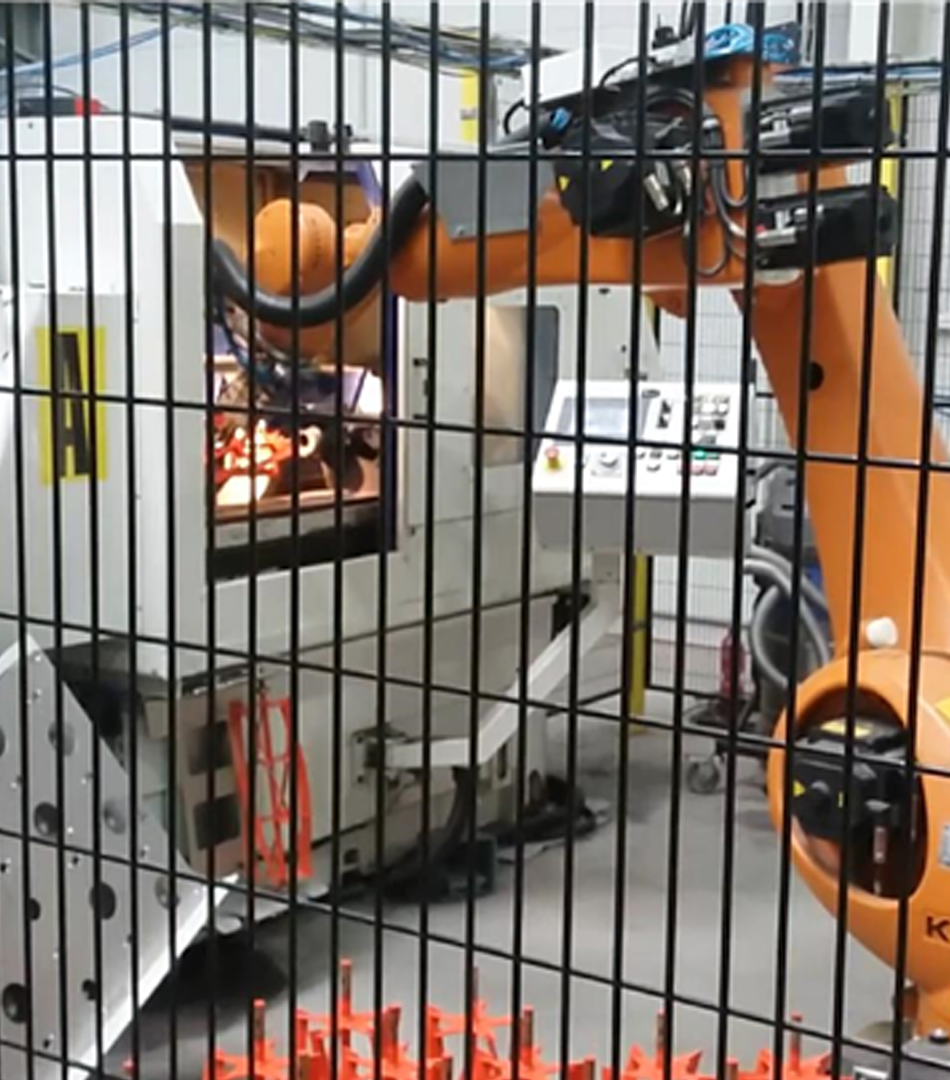

Modernization of a single purpose machining center for machining shafts of railways vehicels with Siemens Sinumerik 840T

Repair of mechanical parts and electrical system

Retrofitting of segment grinder to NC adjustment. Built on X-Solution control system with 12" screen. Efficient and powerful grinding.

Complex modernization with new controller

Modernization of CNC Lathe for turning rail vehicle axles

Provide Modernization to CNC with Simens Sinumerik 840D

CNC lathe for machining rail axles of entire sets directly in the repair depot.

Retrofitting include a new controller.

Specially modified heavy CNC lathe for machining railway axles.

Modernozation of with Fagor 8055 FL/TC

General repair and replacement of the control system of a two-spindle vertical lathe.

General overhaul and replacement of key subassemblies carried out.

Conversion of the grinder to a flat surface. Equipped with servo drives in all 3 axes and an X-Solution control system with a 12" screen. Effective grinding of flat surfaces.

Complete modernization of a machine tool