Lathes made in the Czech Republic

precise piece production and assembly

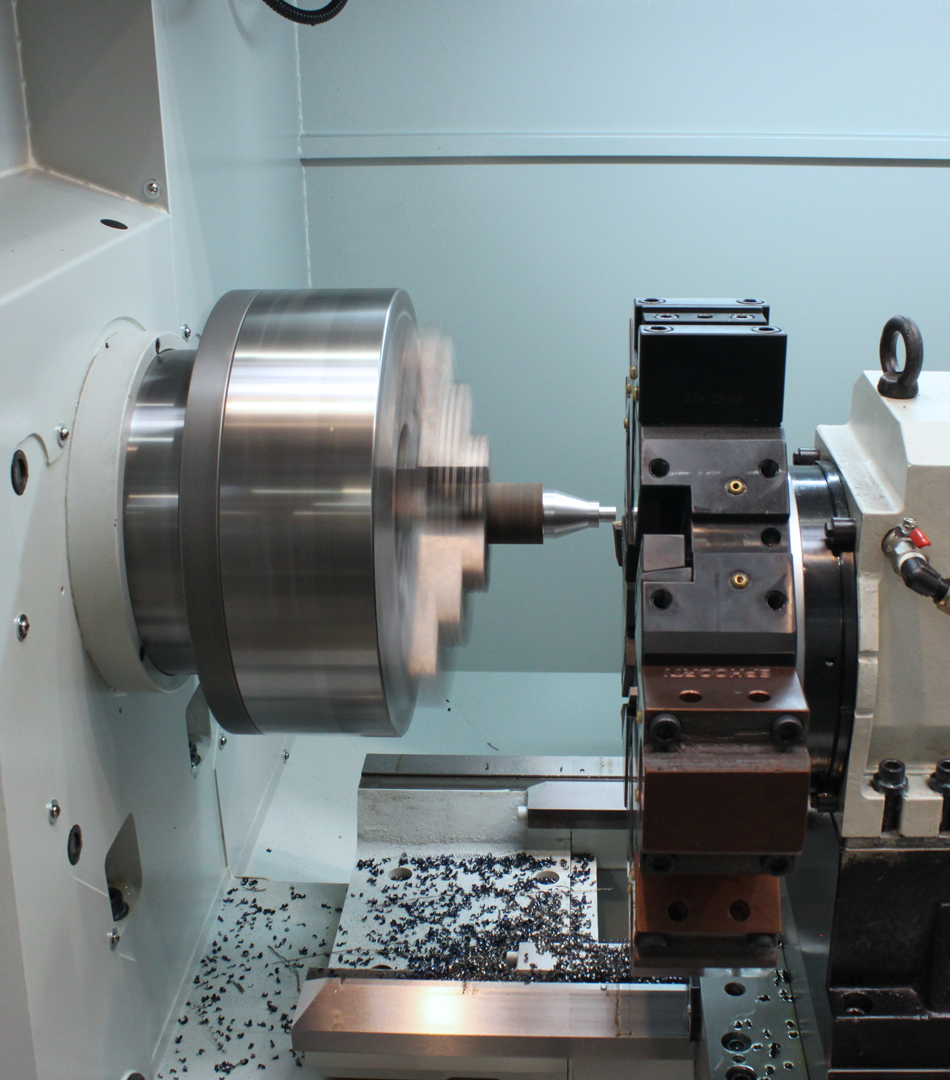

MOOSTURN CNC lathes build on M-MOOS's long-standing experience in building and modernizing CNC lathes for automatic production. They are designed for efficient and precise machining of rotating surfaces. The overall machine concept is based on the company's philosophy: To supply modern CNC machine tools and technologies that will meet the requirements of industrial production in the 21st century.

Thanks to the high degree of automation and precision, MOOSTURN CNC lathes find application in many branches of the automotive and aerospace industries as well as in the global engineering industry in small-batch and piece production. The variability of the system allows us to create customer-oriented programs and deliver turnkey technologies according to the needs of each customer. Even when machining more complex shapes, absolutely no programming basics or knowledge of ISO code are required. The series of these lathes is equipped with an advanced gearbox (a mechanism that increases torque using gears) allowing automatic speed changes in the range: low-medium-high, without stopping the machine. These lathes allow both roughing and finishing operations. The design and performance of the machine is also designed for machining eccentrics or workpieces with interrupted cuts.

| Standard equipment and machine configuration |

| 1 |

Max. swing diameter over bed 560 mm |

12 |

Workpiece cooling system |

| 2 |

Turning diameter over slide 390 mm |

13 |

Work lighting |

| 3 |

Turning diameter when removing bridge 810 mm |

14 |

Electr. version 3x400V /50Hz |

| 4 |

Spindle bore 80 mm |

15 |

Fanuc control system |

| 5 |

Spindle speed 26-2400 rpm |

16 |

Fixed steady rest small |

| 6 |

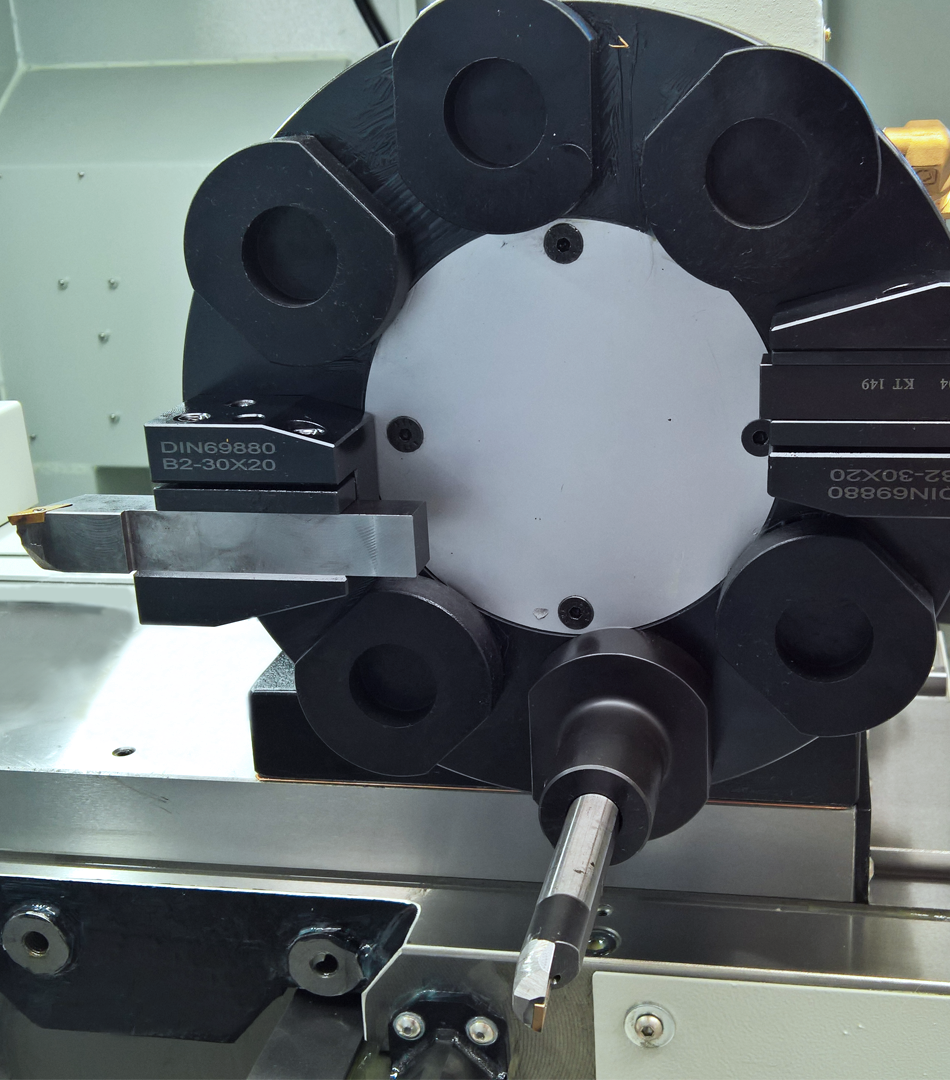

8-position tool head, VDI |

17 |

Movable steady rest |

| 7 |

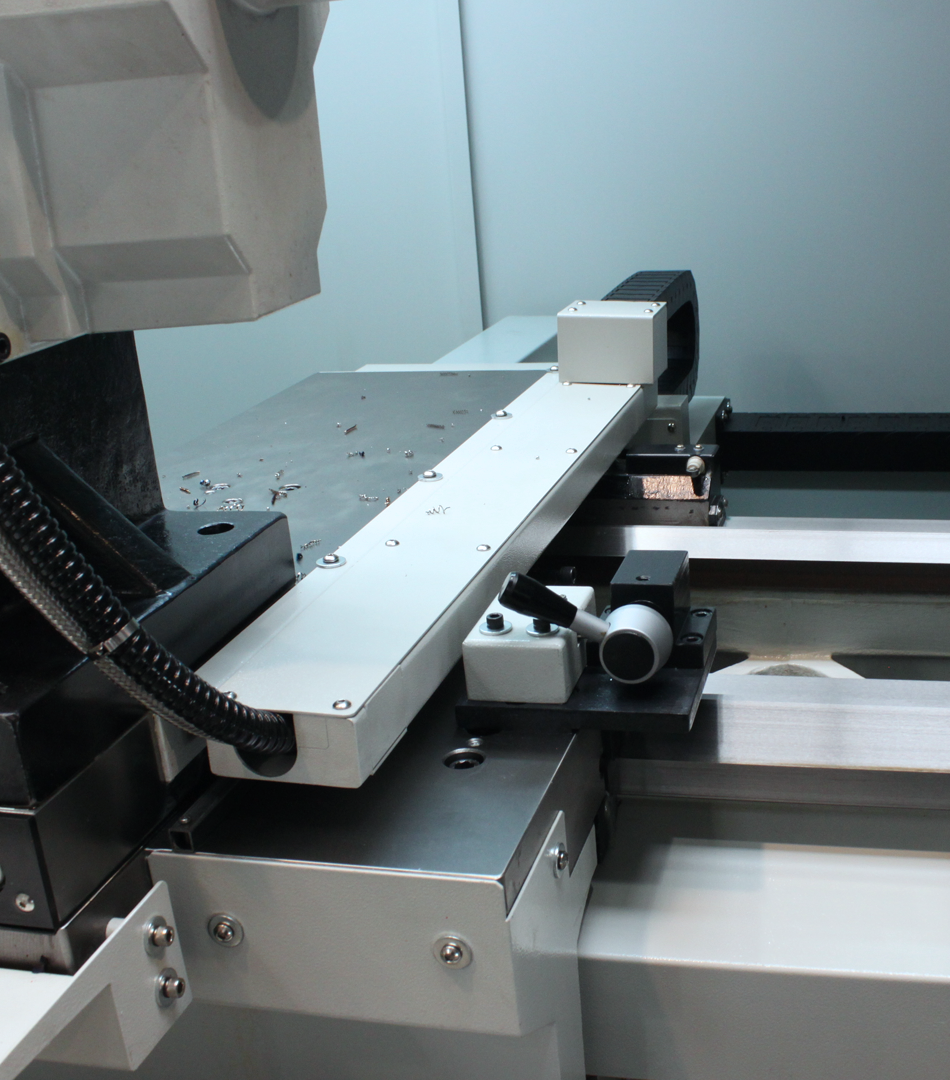

Aut. lubrication system |

18 |

Rigid cast iron construction |

| 8 |

Chip container |

19 |

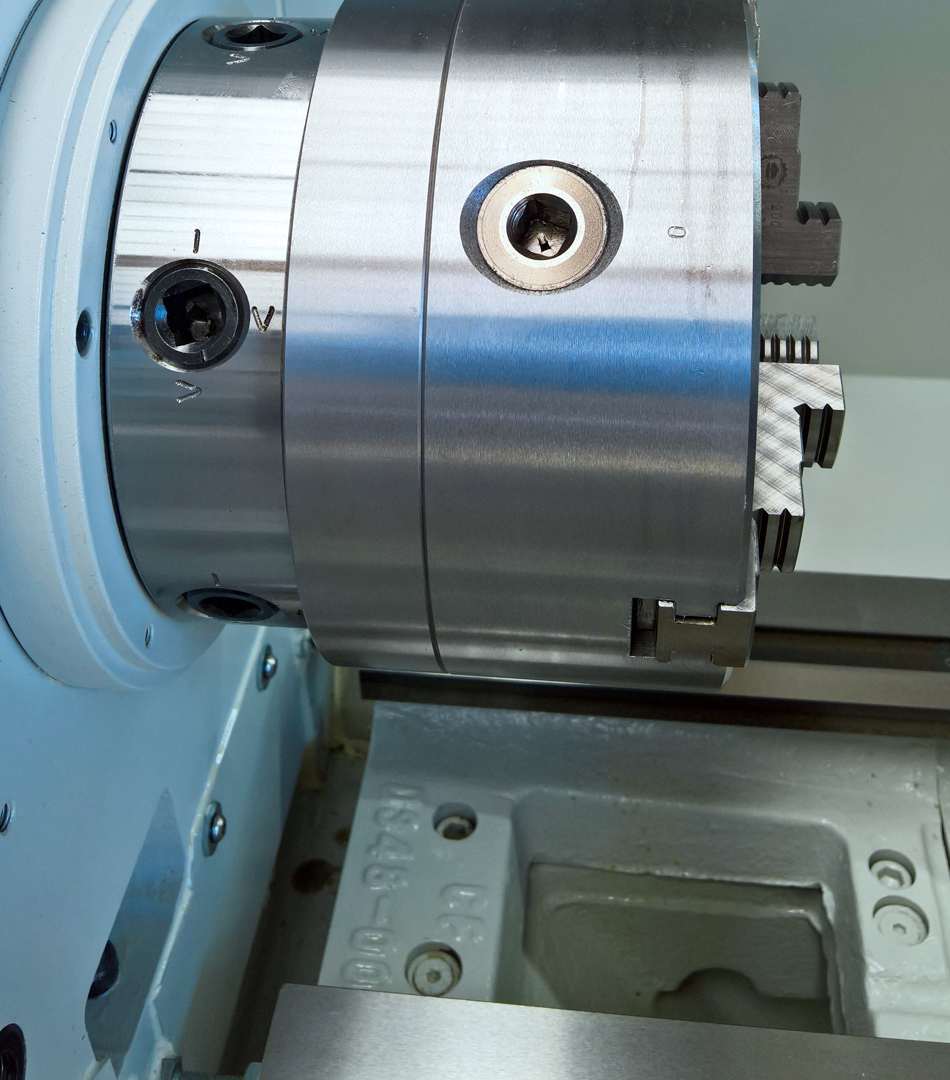

Spindle end D1-8(A2-8) |

| 9 |

Cab cover, 2x doors |

20 |

Operating instructions |

| 10 |

Trailed tailstock with slide |

21 |

Motor power 7.5/11 kW |

| 11 |

3-speed automatic transmission |

22 |

Leveling washers and screws |