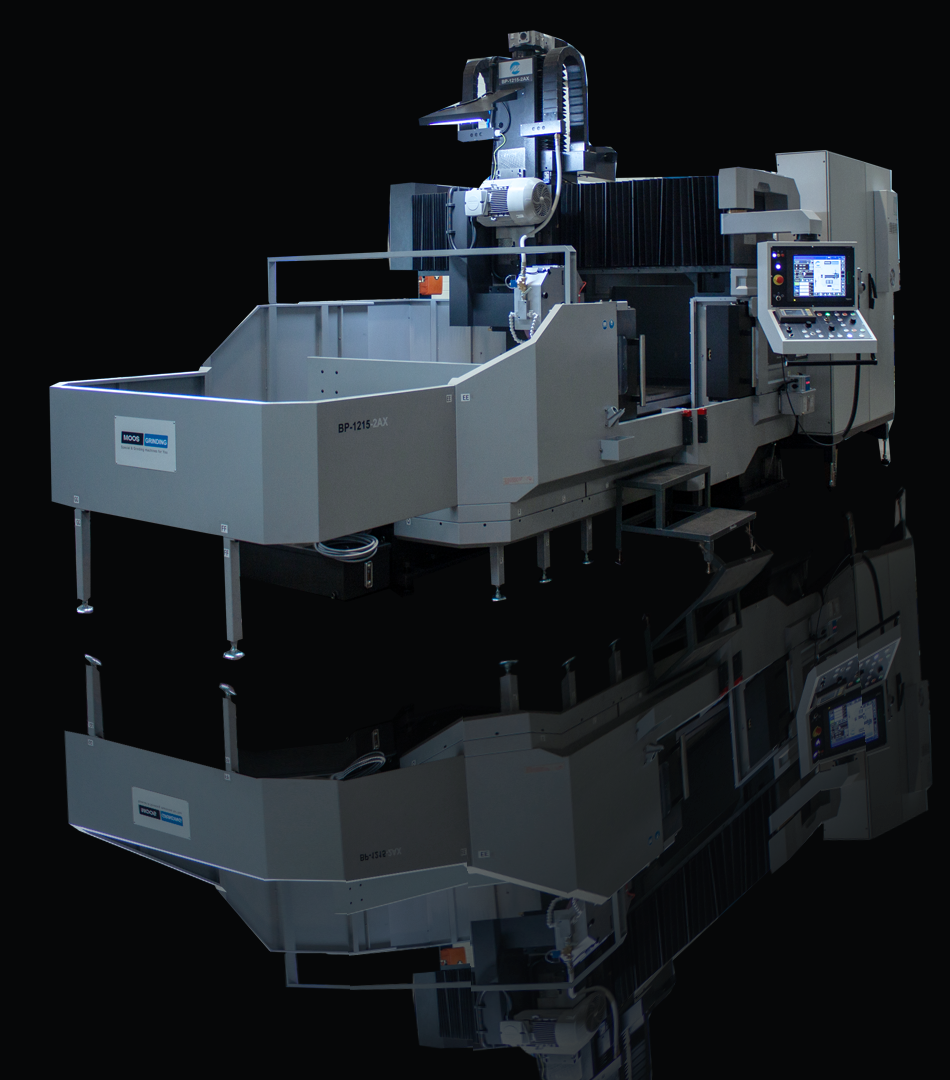

Double column Surface grinding machine

table width 1500 mm

| automatic grinding and dressing | |

| ready for industry 4.0 |

Key features:

- Intuitive and simple operation

- Rigid cast iron machine construction

- Sophisticated and easy grinding cycles

- Superior equipment and machine equipment

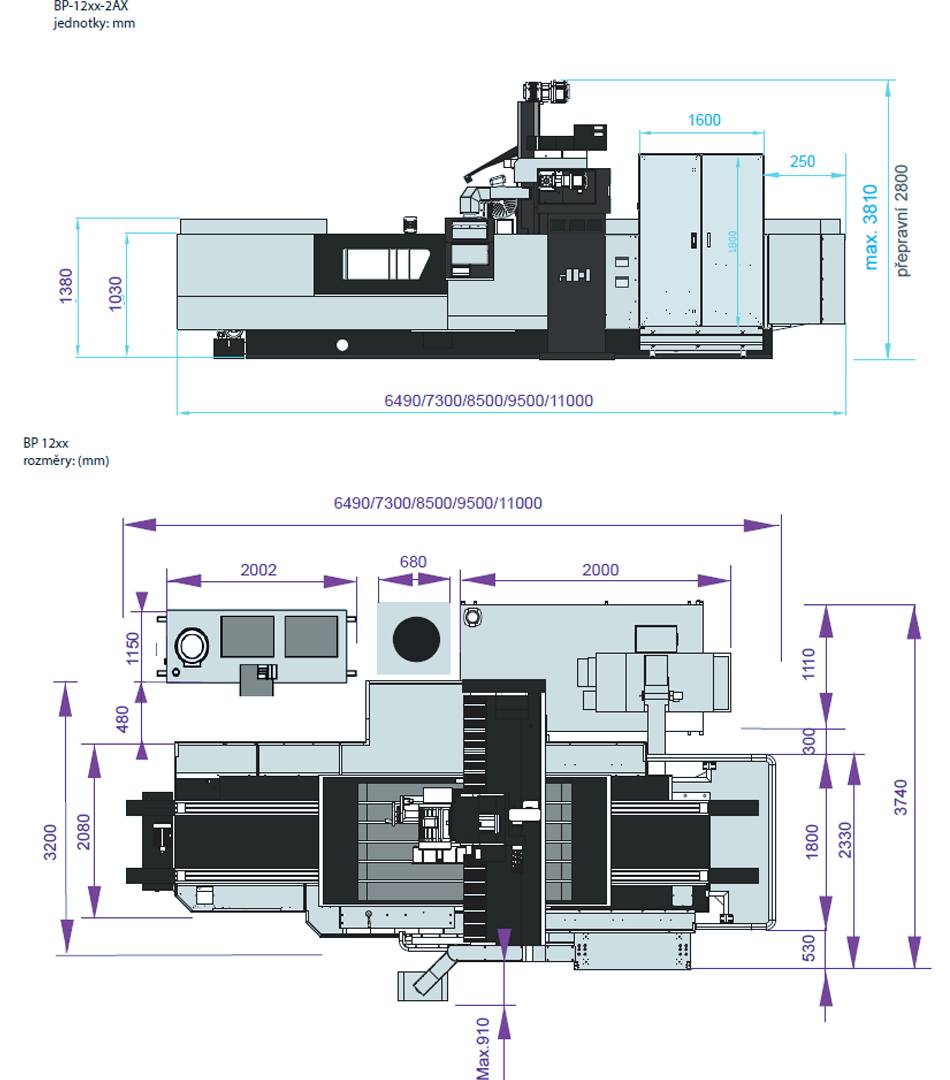

Technical specification:

| Model | BP-1522 | BP-1530 | BP-1540 | BP-1550 | BP-1560 |

|---|---|---|---|---|---|

| Max. travel (mm) | 1900x2350 | 1900x3150 | 1900x4150 | 1900x5150 | 1900x6150 |

| Height of spindle axis from table | 1100 mm | ||||

| Working surface of table | 1500x2200 mm | 1500x3000 mm | 1500x4000 mm | 1500x5000 mm | 1500x6000 mm |

| Move hyd. table | 1-25 m/min | ||||

| Distance between stands | 2000 mm | ||||

| Wheel size (H.D x W x I.D)-standard | 510x100x203 mm | ||||

| Spindle speed 50/60Hz | 1150 rpm | ||||

| Horizontal head motor power | 15 ( 18.5 ) kW | ||||

| Vertical head motor power | 7.5 kW | ||||

| Hydraulic motor | 7.5 kW | ||||

| Net weight | 34000 kg | 39500 kg | 45000 kg | 50000 kg | 56000 kg |

| Gross weight of machine | 37000 kg | 43000 kg | 49500 kg | 55000 kg | 62000 kg |

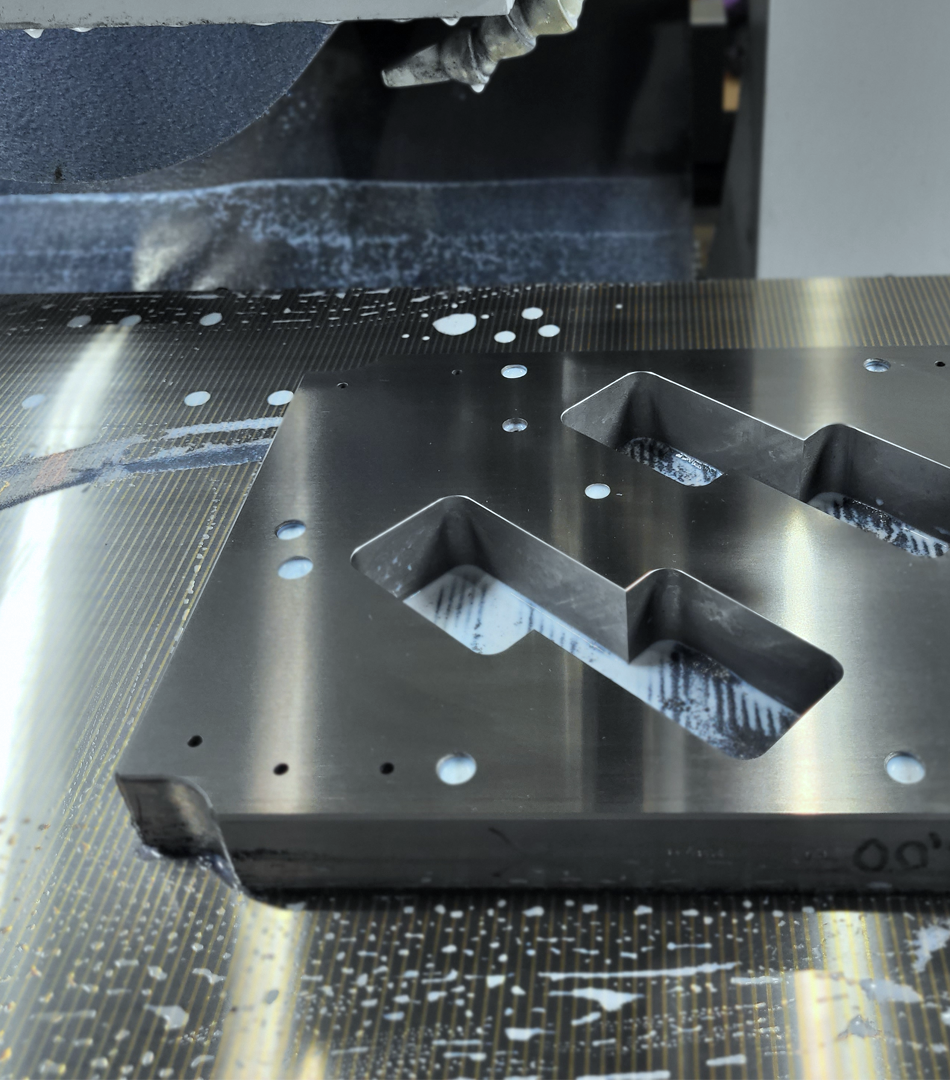

CNC surface grinding machine

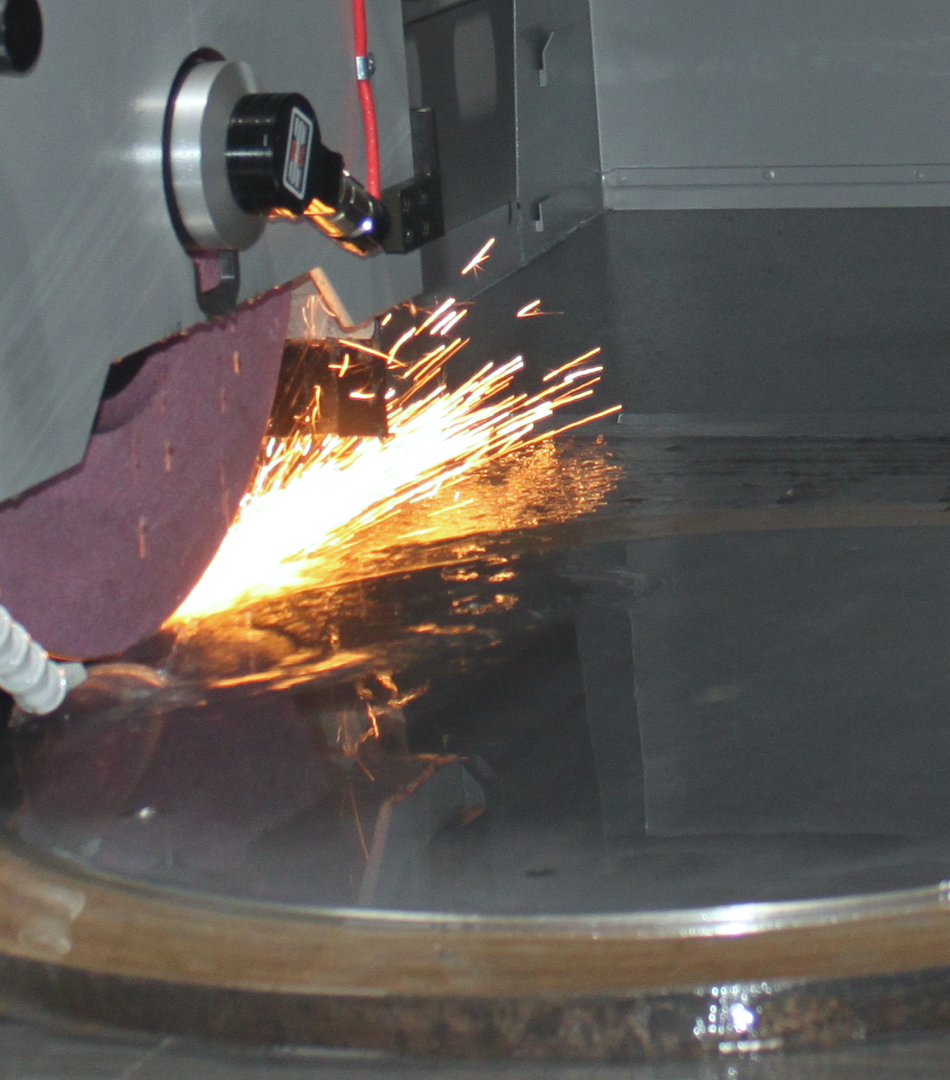

effective flat surface and shapes grindingsThe BP-double column automatic surface grinder is designed for efficient and precise grinding of flat and shaped surfaces. The overall concept of the machine is based on the company's philosophy: To supply modern grinding machines and technologies that will meet the requirements of industrial production in the 21st century..

Machine using:

Thanks to the high degree of automation and precision, M-MOOS surface grinders find application in many branches of the automotive and aerospace industries, in the production of tools, molds and also in the global engineering industry. The variability of the system allows to create customer-oriented programs and to supply technologies according to the needs of each customer. Even when grinding more complex shapes, absolutely no programming basics or knowledge of ISO code are required.

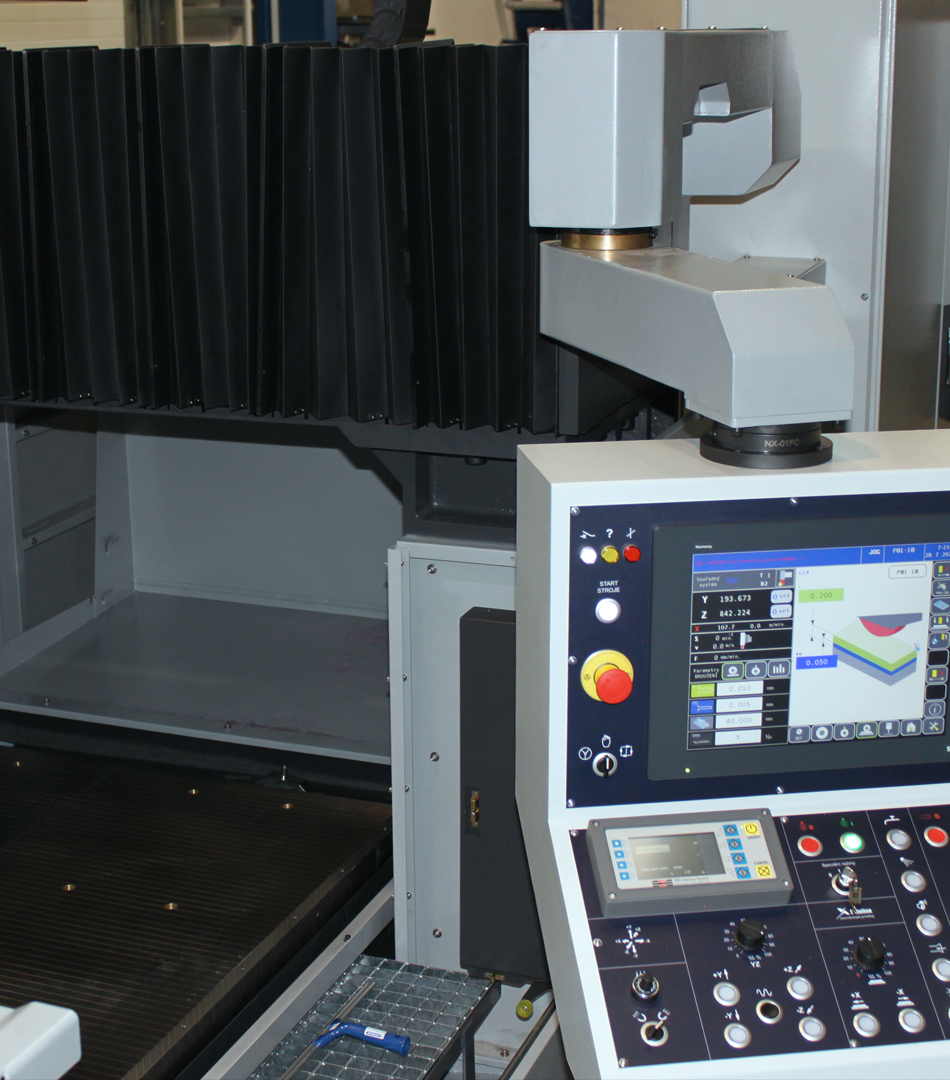

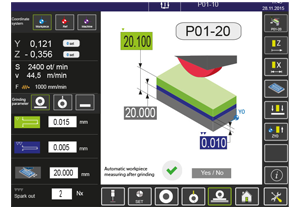

Control system

+ Intuitive and simple operation

+ Reduced time delays

+ Faster program creation

+ Possibility to update and add new macros

+ Sophisticated machine management

Explore

| Standard equipment and configuration |

|---|

| Electromagnetic table ( chuck) |

| Automatic demagnetizer |

| Height of the spindle axis from the table 1100 mm |

| Grinding wheel + flange |

| Spindle speed 1500 rpm, stepless regulation |

| Siemens spindle motor with frequency converter |

| Hydraulic longitudinal feed, proportional valve |

| Schnider servomotors in Y and Z axes |

| X-SOLUTION control system + 15" color touch screen |

| Cooling system with paper filtration and magnetic separator |

| Operating instructions in Czech |

| Automatic wheel balancing system |

| Linear rulers in Y and Z axes, accuracy 0.001 mm |

| Leveling device on the work table |

| Rinse of channels + gun for rinsing the working area |

| Half-cabin cover, 2x front doors according to CE standards |

| Automatic lubrication system |

| Maintenance tool set + plastic box |

| Work light |

| MPG- Electronic hand wheel |

| Balancing stand + arbor |