Radial column drill

VR 50

Key features:

- Easy to operate

- Reliable feed and speed control system

- Rigid cast iron construction

- Motorized controlled arm lift along the column

- Hardened and ground arm guide surfaces

Technical specification:

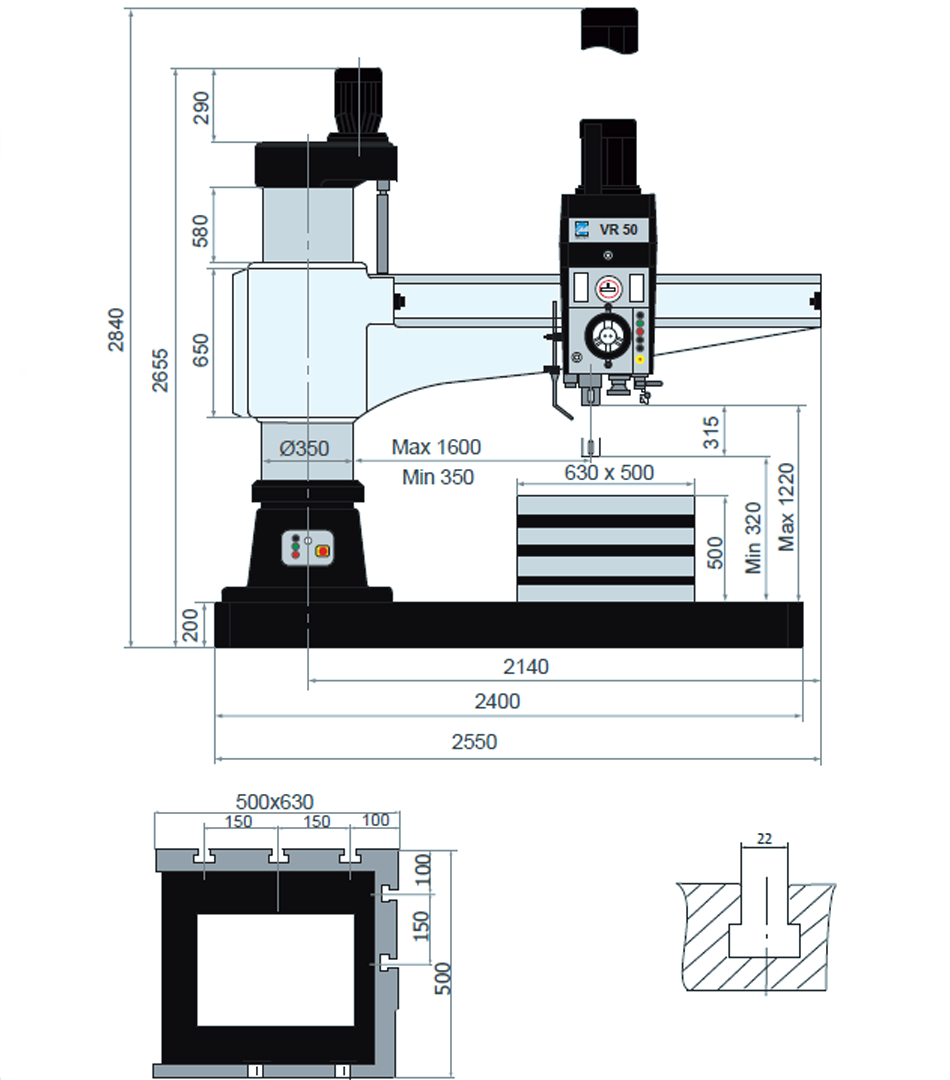

| Type | VR 50 |

|---|---|

| Max. bore diameter (mm) | 50 |

| Spindle-column distance (mm) | 350- 1600 |

| Distance from spindle tip to base surface (mm) | 320-1220 |

| Spindle travel (mm) | 315 |

| Spindle taper | 5# |

| Spindle speed (rpm) | 25 -2000 |

| Number of gears | 16 |

| Drilling block size (mm) | 500×630 |

| Headstock travel (mm) | 1250 |

| Main motor power (kW) | 4 |

| Machine net weight (kg) | 3500 |

| Overall dimensions (l×w×h) (mm) | 2500×1070×2880 |

Radial drilling machine

powerfull and rigid drilling machine Industrial radial column drills enabling drilling, tapping, and aligning a wide range of workpieces. The design is based on classic radial drills manufactured in the former Czechoslovakia.

These are sufficiently rigid, precise, and powerful machines with a long service life. Compared to older types, such as the VR 4A, current drills provide a simple, fast, and most importantly, reliable system for changing speeds and working feeds.

The best-selling type is the VR 50 drill. This drill with a Morse 5 taper has the same rigidity and size as the VR4A

The VR 50 is the optimal solution for most tool shops that need to make holes up to Ø50 mm and threads up to M30. If you require larger diameters, we recommend choosing the larger VR 63 or VR 80 models, which have a more powerful spindle motor and overall rigidity.

Main advatages of VR series VR

+ High versatility

+ Hydraulic headstock, column and arm reinforcement

+ Easy to operate

+ Reliable feed and speed shifting system

+ Rigid cast iron construction

+ Motor-controlled arm stroke along the column

+ Hardened and ground arm guide surfaces

High torque required for power drilling and tapping

| Drilling | Threading | ||||

|---|---|---|---|---|---|

| |

VR 50 | Ø 50 | VR 50 | M40/M30 | |

| VR 63 | Ø 63 | VR 63 | M50/M40 | ||

| VR 80 | Ø 80 | VR 80 | M60/M50 | ||

| Standard equipment and machine design |

|---|

| Motorized arm travel |

| Hydraulically controlled column and arm reinforcement |

| Workpiece cooling system |

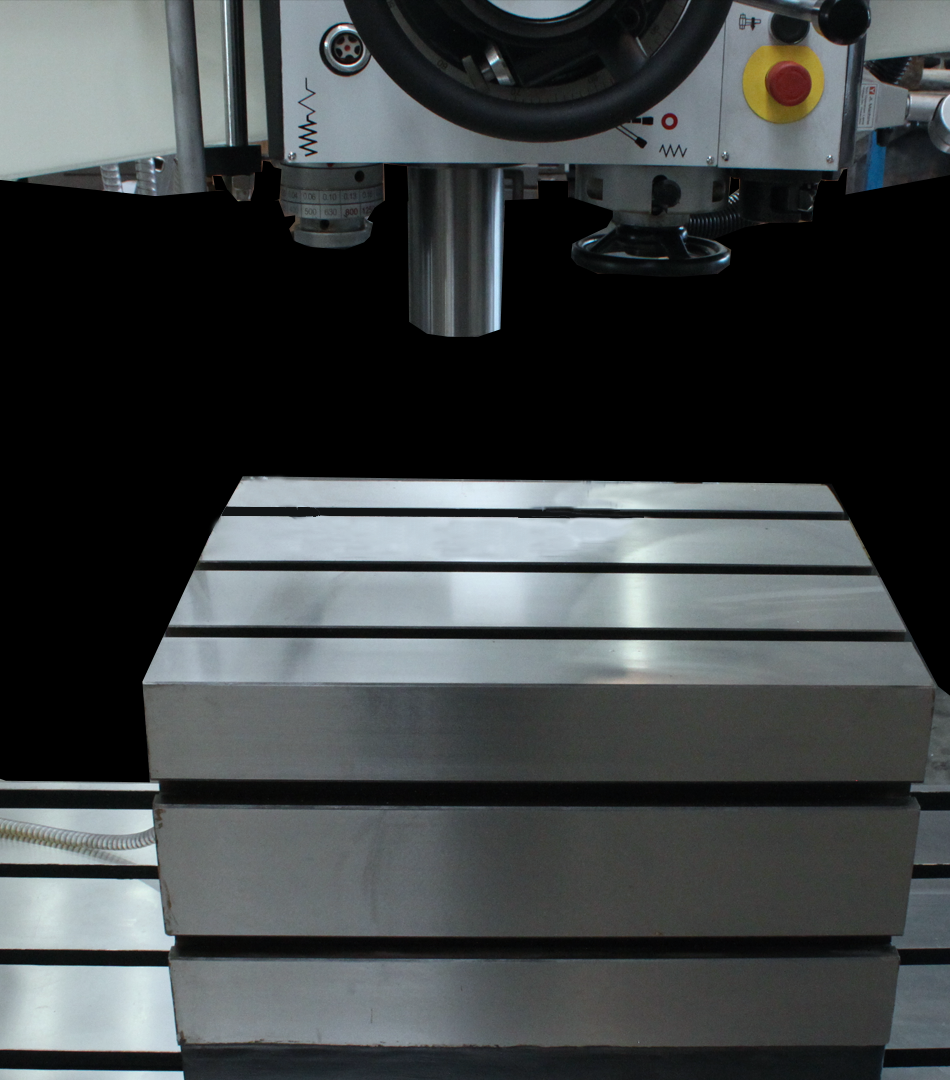

| Drilling block – work table |

| Solid cast iron design |

| Hydraulically controlled headstock reinforcement |

| Work lighting - LED |

| Grounded surface of the drilling block base and clamping surfaces |

| Automatic lubrication system column guide surfaces |

| Arm movement up (arm release occurs at the same time) |

| Geometric accuracy protocol |

| CE declaration of conformity |

| Electrical equipment audit report |

| Original electrical diagrams in Czech Republic |

| Spindle safety cover – automatic shutdown when opened |

| Black-gray: RAL 7021 and white: RAL 9003 |

| Operating instructions |